Our quality

Since 1979, our mission has been to be a trusted long-term technology partner for our clients. We constantly enhance our processes, products, and services, guided by a commitment to excellence. We adapt to technological shifts and collaborate closely with clients to meet their evolving needs.

Our goal is not just to serve, but to build lasting relationships based on trust sand shared success. Looking ahead, we are driven by a will to be the technology partner, characterized by reliability and a shared vision.

Quality of operations

The goal of all Tasowheel operations is a satisfied customer. Our quality policy places a heavy emphasis into achieving an effective production system. We serve our customers in a professional and reliable manner, meeting their various needs with both finished products and comprehensive planning through close collaboration. This results in competitive products and services that fulfill our customers’ quality and schedule expectations.

To ensure premium service, we are continuously tracking our customer satisfaction levels. We build and maintain active relationships with our stakeholders. Furthermore, we strive for a future of long-term trusting relationships with our interest groups and cost-effectiveness in all of our operations.

Our supply chains and processes are subject to constant assessment and continuous improvement. Staff competencies are ensured and advanced via various forms of training. The quality of our processes is ensured by operations in accordance with the ISO 9001:2015 and ISO 14001:2015 standards. Each Tasowheel employee is responsible for ensuring full compliance with quality standards in their work.

Quality objectives

The Tasowheel organization is driven by a set of quality objectives that form the foundation of our operations and growth strategy. These objectives include maintaining steady business growth and profitability, improving operations based on standards and customer feedback, ensuring a reliable supply chain, and continuously enhancing all aspects of organization. We are dedicated to innovation, customer satisfaction, and a culture of improvement, with the ultimate goal of achieving lasting success, and positive impact in the marketplace.

Product & service quality

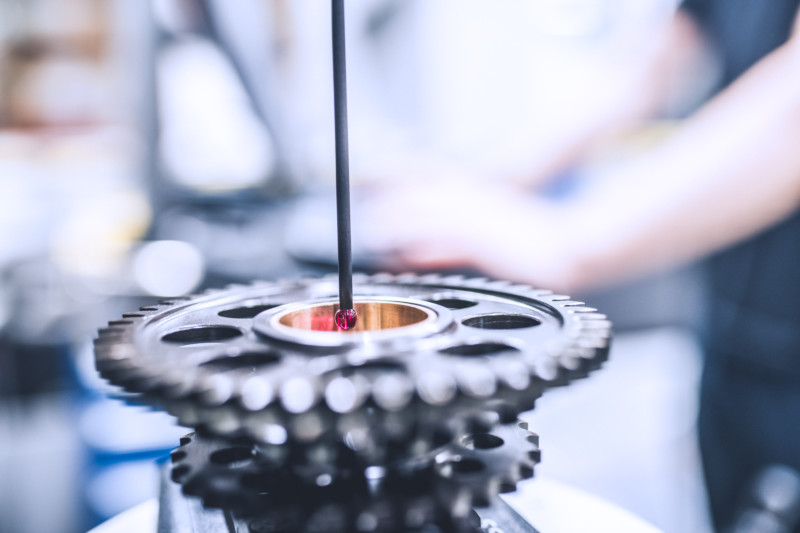

We take product and service quality very seriously. Customer-specific quality requirements such as different standards are taken into consideration in every stage of our process. Only by constantly controlling our production processes can we guarantee high-quality products and services.

Our production processes follow customer requirements and also some requirements of the IATF 16949 (former ISO/TS 16949) standard. We are familiar with Advanced Product Quality Planning (APQP), Control Plans, FMEA and Production Part Approval Process (PPAP).

Our customers audit us regularly according to their own or other international quality standards, such as VDA 6.3. These audits are often very detailed and product-related, which is a key factor in improving our performance. As a result, close collaboration is always satisfactory for both parties.