Paper Quality Control Systems

From simple standalone solutions to complete quality management systems

Tasowheel delivers actuators, components and complete turnkey profiling systems including market-leading cross-machine direction (CD) controls and paper quality measurements (QCS)

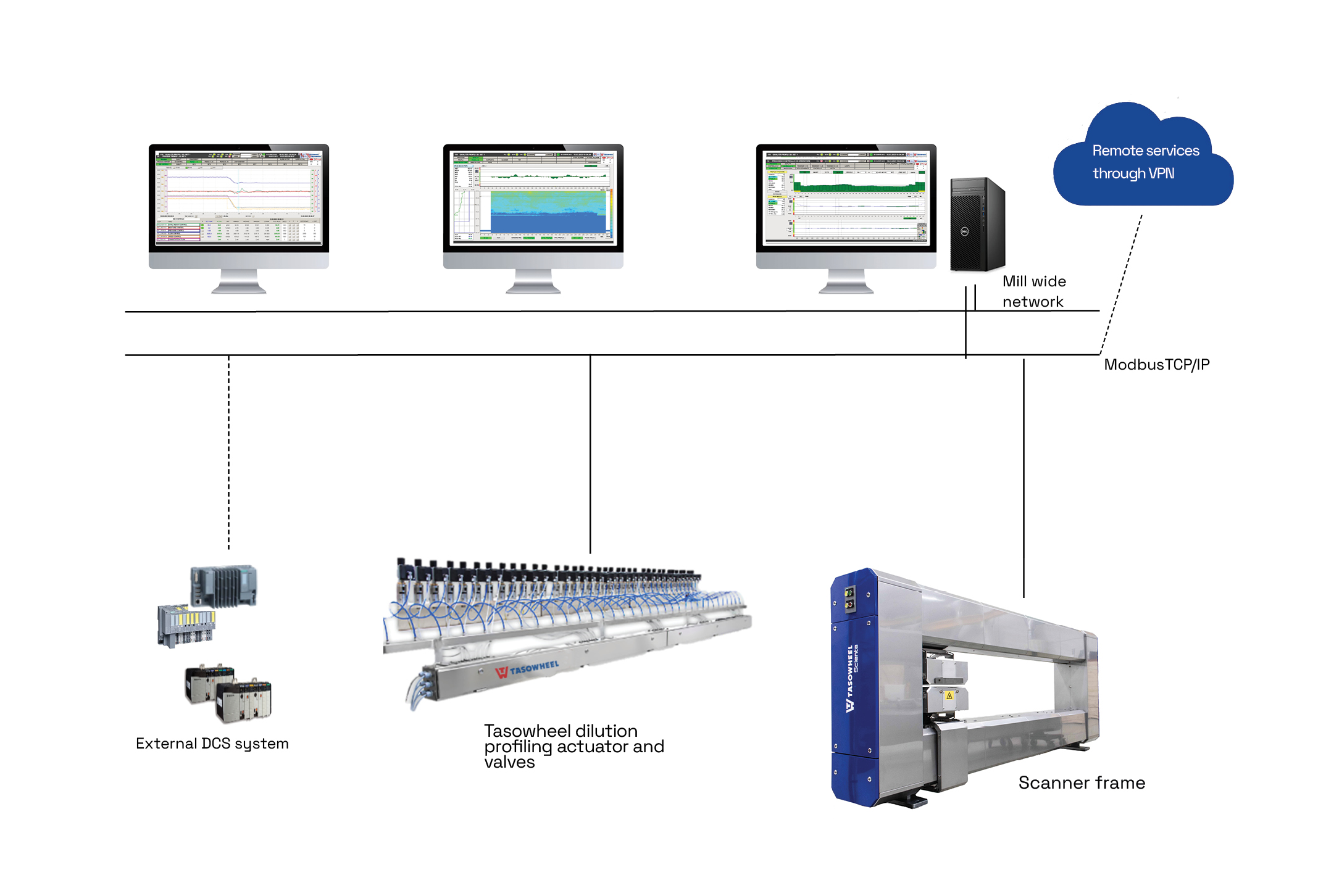

Control Systems

Our open QCS systems are designed to be connected with your other equipment and machinery without expensive licenses or complicated integrations.

We always customize the delivered systems to match your production environment and specifications. Compact designs and high-quality durable actuators guarantee easy maintenance and low life-cycle costs.

- Open network and system with commercial automation equipment

- Control system available for all profilers: Dilution headboxes, steamboxes, moisturizers, coating control and caliper control

- System for all paper machines: board, pulp dryers, tissue machines, non woven, converting, coating and calanders

- Easy and cost efficient communication to other systems with all modern interfaces

- One common industrial network with various communication protocols

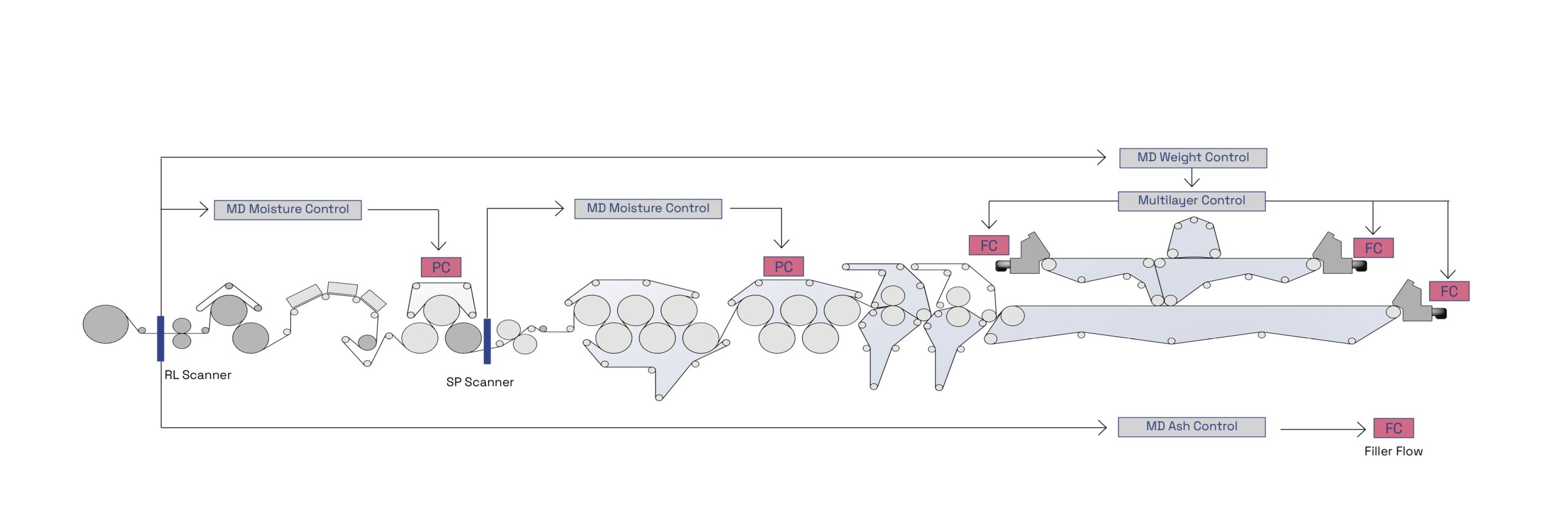

MD Control

Tasowheel’s Machine Direction Controls utilize industry-proven model-based control technology, to improve product quality and paper machine efficiency while minimizing material and energy usage.

MD Control package is fully scalable and by using dynamic process models it can be separately tuned for operation of the entire range of production. The Automatic Grade Change application ensures fast and accurate grade changes.

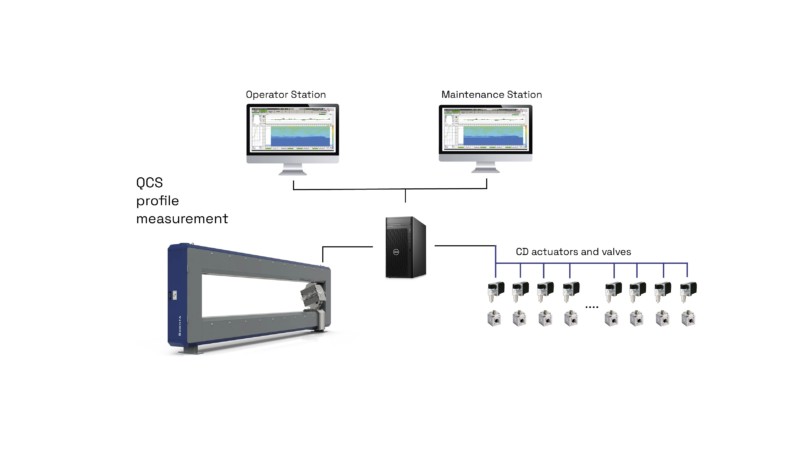

CD control

Our cutting-edge controls offer precise CD profiling with a simple user interface, ensuring accuracy and ease of use.

Experience accurate mapping of actuators to control profiles, allowing for dynamic mapping and optimal performance. With high resolution profile optimization and adaptive control capabilities, our system ensures exceptional control performance and fast recovery after upsets. Benefit from absolute position tracking of actuators and access diagnostic engineering displays for comprehensive insights.

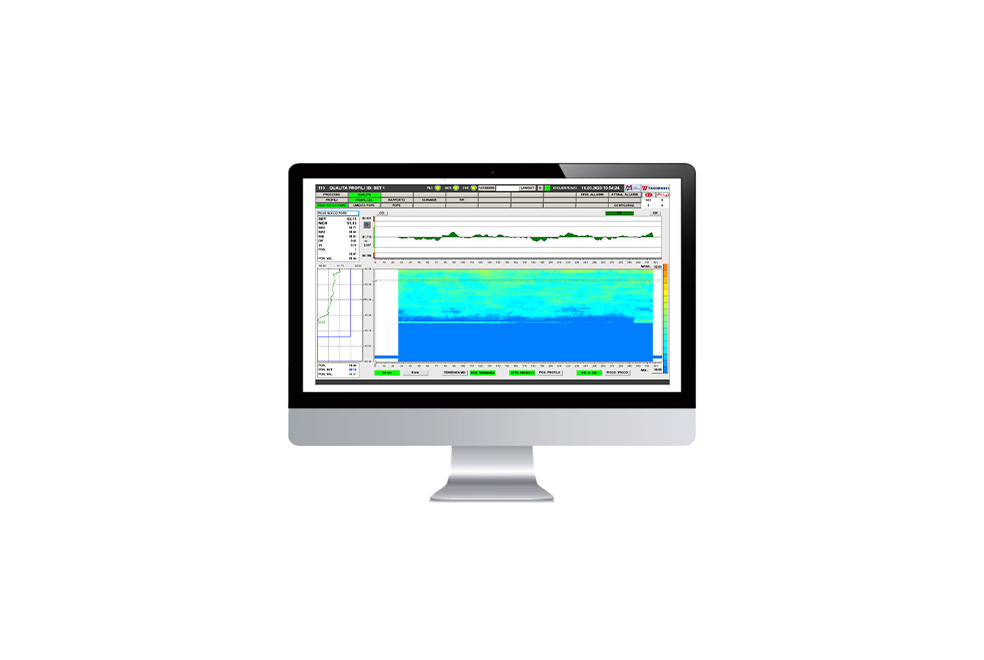

Report & Analysis

Access real-time profile and reporting data from our advanced Quality Control system. Our system ensures periodic data collection, enabling long-term historization and in-depth analysis. All data is conveniently stored in Excel format, and historical reports can be easily browsed by specific criteria such as date, reel, grade, shift, or day. Additionally, our system allows seamless data export to any software application capable of handling CSV files. Integration with Mill ERP systems like SAP is effortless, providing a comprehensive solution for optimizing your quality control processes.

References

Contact us

Send us a message