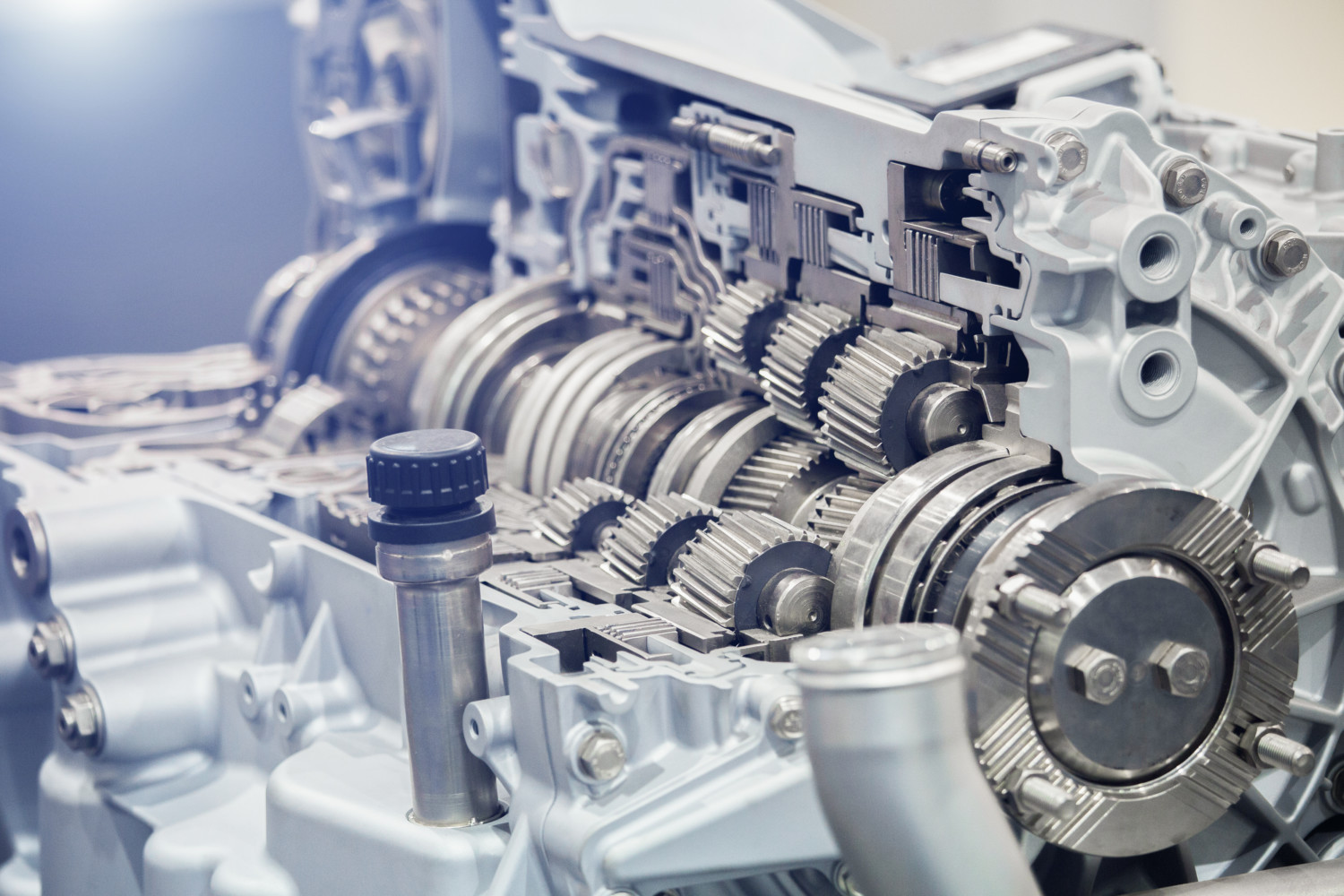

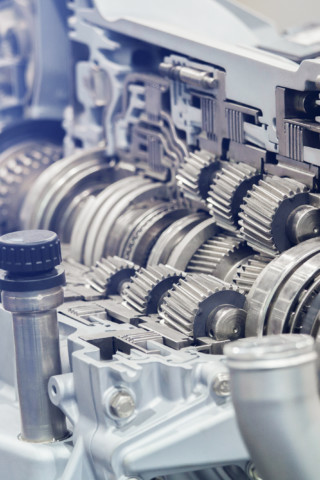

First class solutions for your transmissionassemblyR&DQCSmachiningtransmission

needs.

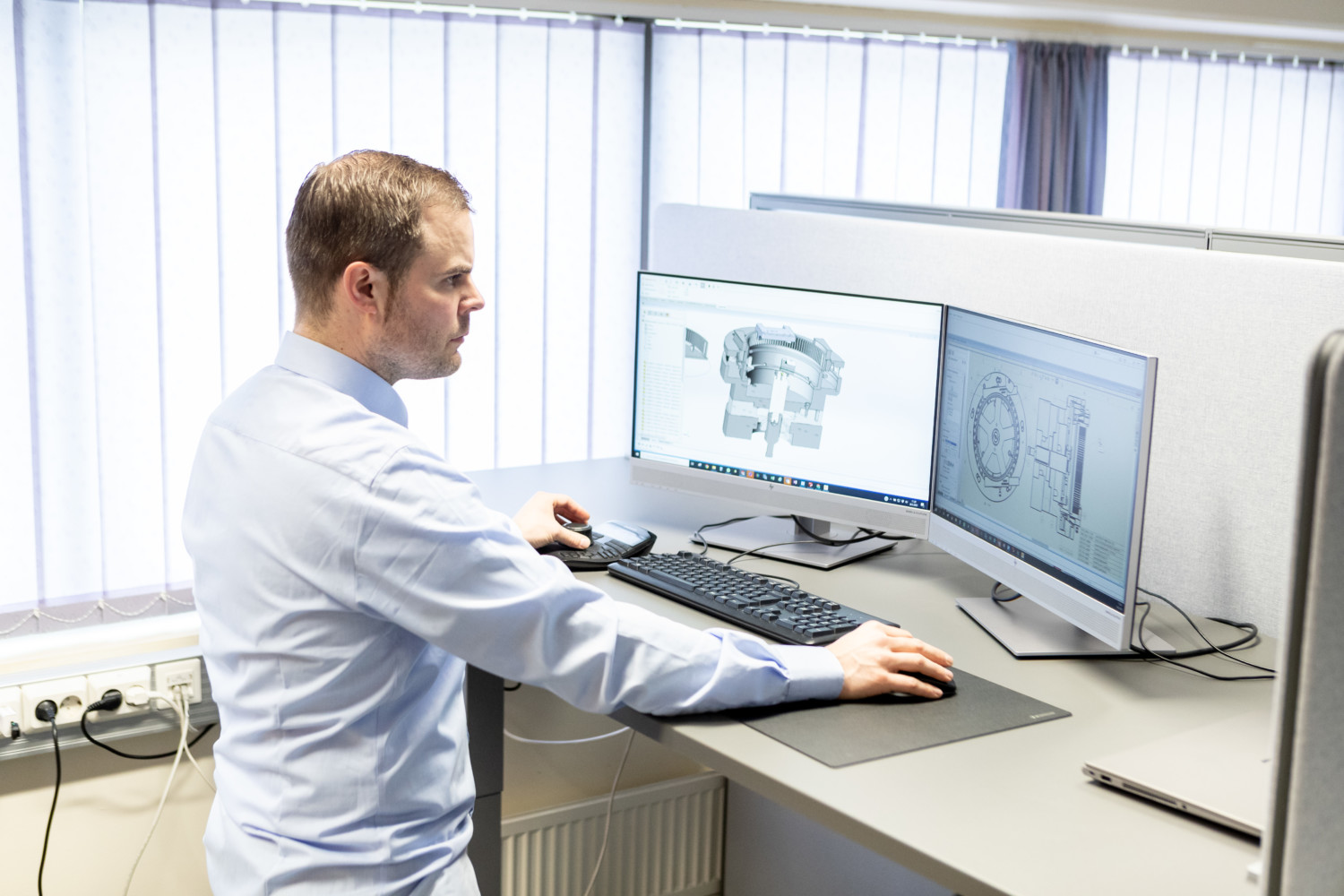

Tasowheel is a family-owned Finnish company with over 40 years of experience in providing premium customer-specific solutions. We design and produce components and services for different power transmission, controlled motion, machining, paper industry, assembly, and R&D needs.

Products & Services

Can we help you find a solution?

Most recent successes with our clients

We serve industries from A to Z

Don’t see your industry here?

Let’s find a perfect solution for your needs.

Latest content in Knowhow center

We’re hiring

Are you the missing piece of our machine? If a gearwheel is missing a tooth, the whole system suffers. No great things are achieved alone, and that is why we think we are nothing without our people.