How to choose the optimal linear motion solution, part 2: Belt and rack & pinion drives?

In our series of motion solutions, we have previously presented motion screws as a linear motion solution. Now we will introduce two other options. Belt-driven actuators are characterized by high efficiency and simplicity meaning they are a suitable choice for applications requiring long strokes and lower loads. However, if the application requires durability, a rack and pinion system might be a better option since with adequate lubrication they can last for hundreds of millions of cycles before needing replacement.

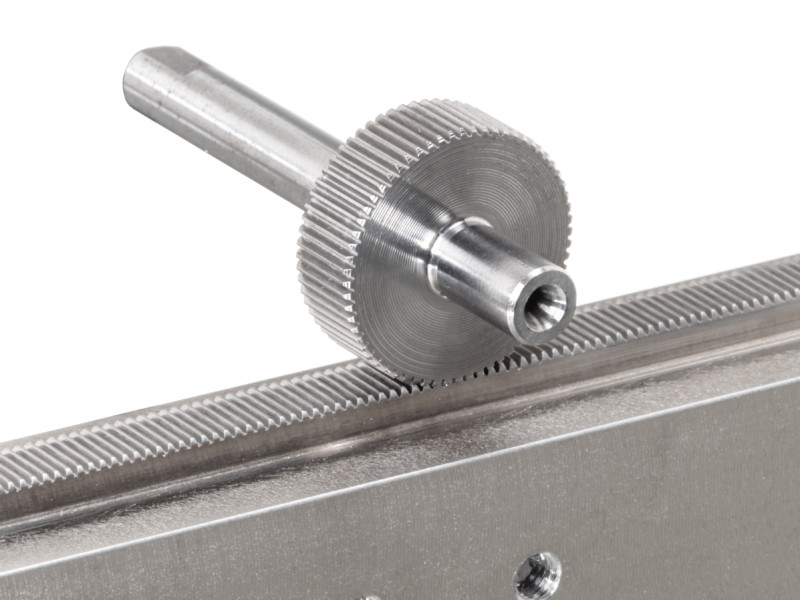

Rack and pinion drives

Rack and pinion drives are often overlooked as past-generation technology with limited motion and positioning accuracy, but this is not the case. The performance of rack and pinion solutions has improved by using high-end machining, grinding and surface finishing solutions. Rack and pinion systems can offer smooth movement, superior positioning accuracy and unlimited travel distance in a compact size at reasonable costs.

Regarding acceleration and speed, the rack and pinion systems allow faster movements and higher speeds than motion screws, which may begin to suffer vibration, a so-called “screw whip”, at higher speeds. For the same reason, the motion screws are not optimal for longer travel distances with long spans between bearing supports.

Rack and pinion solutions are also extremely resilient to contamination in harsh environments. With adequate lubrication, the rack and pinion systems can last for hundreds of millions of cycles before needing replacement.

Rack & pinion properties:

- Cost-efficient solution

- Simple and robust design

- Compact size

- Modern machining allows high performance and precision

- Allows high acceleration and speeds

- High efficiency

- Long lifetime

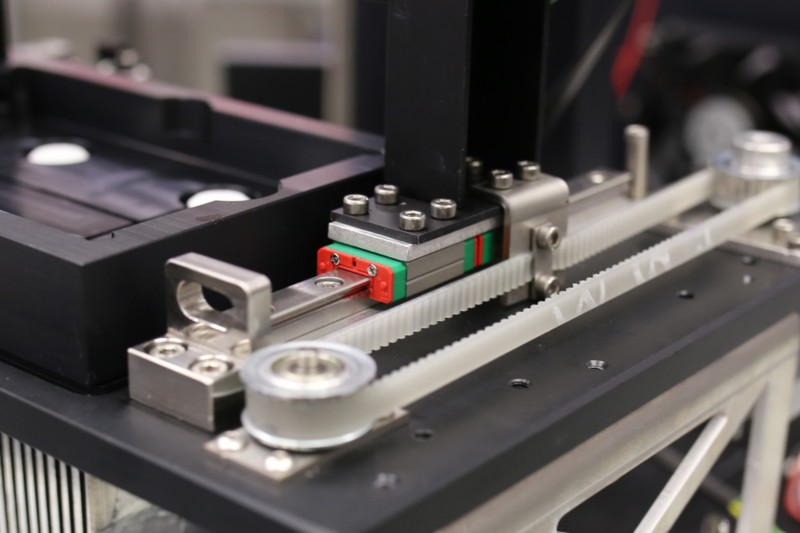

Belt drives

Belt driven actuators convert rotary motion to linear motion by utilizing a timing belt connected between two pulleys at either end of the drive. The timing belt is typically constructed of a fibre-reinforced elastomer for light-duty applications, or steel-reinforced polyurethane for more demanding requirements. It contains teeth that mesh with pulleys to prevent slipping.

Due to high efficiency and simplicity, the belt-driven actuators are a good choice for long-stroke applications with lower loads, especially when high speeds are needed. On the other hand, belt drives cannot transfer high loads or achieve high accuracy and repeatability over time due to the stretching of the belt.

Belt drive properties:

- Long travel distances

- High efficiency

- Cost-efficient

- Not suitable for high loads

- Need for maintenance